Is there provision for using a samll DBW throttle body on the intercooler piping as a means to control or maintain boost?

EMU Pro is able, not the black and classic

Oh Darn. Was hoping it woudl be possible with the Black. I see some people using a mac valve directly on the BOV as well. Maybe this can work as a go around?

Any chance softare may allow the secondary H bridges to be used as such?

Mac valve can be run on a PWM table, or on/off with parametric outputs. More simple then a 2nd bridge with it’s own control loop etc.

Software does not allow for custom use of H bridge outputs like the Pro does.

Ok Mac valve on BOV is the way on the Emublack for me then.

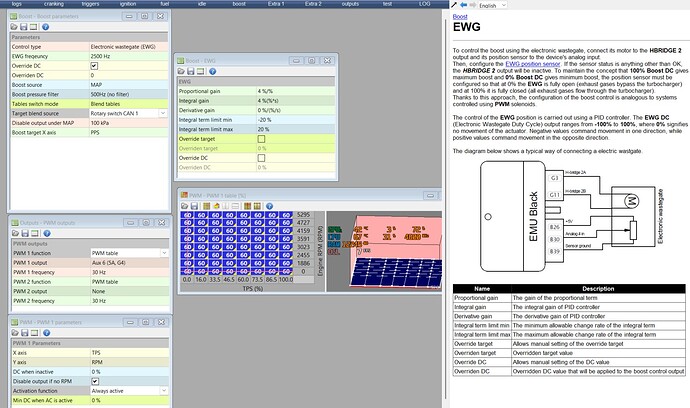

So going through the software I went to outputs and found the PWM outputs. Is it possible to run aux output to mac valve. Assign PWM output to PWM table. Build that table as map vs RPM let that mac valve build required boost and keep that boost in whatever rpm range. Then in the boost section assign EWG and hook that up via Hbridge 2a and 2b to dbw tb on the intercooler piping and use that as my boost control? Essentially using PWM output table as a custom table to build and keep turbo in its efficiency range. And then use the EWG settings via a dbw tb to bleed off boost as i see fit per gear per speed etc?

I don’t actually see a reason this couldn’t work. at least on V3. V2 my understanding of EWG use was a PWM controlled type without feedback but perhaps that’s been updated since, the help window is blank. V3 on the other hand is much more built out now then even a few months ago

Using V3 firmware you can build in all the safeties and such that the normal method of controlling boost would have using Functions. Lose table switching but that’s probably an acceptable trade off.

PWM table controls a traditional mac valve/wastegate and is tuned to roughly get the turbo in the target ball park (it’s not going to have any closed loop correction since the DBW bleed will do that). I actually know of a 1100 hp 2JZ car doing this but with a turbosmart E gate and black box. it feeds bled off air back to the turbo’s compressor intake. offer’s great boost control, they can command like 300 whp up to 900 (Nitrous fills the rest). It’s running a Pro16 mind you…

I would totally try this with cautious optimism lol. definitely want to make sure you can safely tip toe into it and make your boost safeties tight to start with.

We run control like this just about anywhere we can. Turbo setup, pro charged or with Hemi and LT5 blowers. Turbo smart straight valves can be run on an 8 amp h bridge without their black box. The main function of the black box is to keep the TS motors alive, crashing them hard kills the motor very fast.

Basically you would setup a blade DC call out and then use the boost control to call that DC. Then scale the PID based on airflow, because the higher the airflow the stronger the PID will need to be.

On turbo setups, we have run no wastegates and only bypass on the charge side. Worked excellent. You can base majority of the boost control on the shaft speed. Open valve, unload air, raise shaft speed with no change to air entering engine. Same theory on hot compressor. Unload compressor load and the air will cool.

In staging you can now build shaft speed without EGT and negative timing. Same for TQ reduction or TQ feedforward.

Thank you so much. Many peolle cant seem to understand the concept. I was 2 secs away from selling my black for a haltech r3. As its easier on my pocket and easier to do custom tables. But this gives me more hope. I’d like as much info on this as possible. I’m a 2.3 4 cl. And I want to use a large turbo for drags.

Have you/Can you do this on a Black?

Even on V3 I don’t see a way to do anything more then log turbo shaft speed, no corrections on boost EWG dc based on shaft speed. the PID isn’t scale-able and the black logs “estimated airflow” not sure how that differs…

I have a Pro8 and been contemplating doing a dump valve like this pre TB and bolting the wastegates shut since the turbo position of my build has been tough to get the IWG actuators to fit. Pro seems like the way to do this as it’s software is much more flexible. Perhaps with Functions in Black V3 you can set safeties around shaft speed limits…

You have to have the ability to setup the second H Bridge with full PID control. Its almost like setting up an initial DBW throttle and reassigning it. Pro ECU it can be done in the custom DC motor, I just wish we could have multi axis on the PID or feed forward for pid from a custom table.

I bet you could use a CAN H Bridge controller to run one. We’ve run an H Bridge controller for upper LED light bar control, vertical aiming. Made speed and body based positioning that was requested over CAN. Would be very similar.

We generally will use the hellcat bypass valve or the LT5 internal bypass valve as they are open limp. Bosch makes smaller ones for smaller setups. Also remember round is not linear with respects to blade position and flow when scaling a DC conversion to boost control.

The more info you guys give the more I feeling to switch to haltech r3 and use this black on a second project not drag race related. I was looking to use second hand dbw tb of a chevy spark I think it is either 44 or 54mm and put it directly on end tank of intercooler. Switching to R3 saves money with build in pdm as I was going to buy a pdm to add to the black. Would have been nice if the firmware allowed me to use secondary dbw tb independently and as you said 3d table or 3rd axis. Thanks so much for the info.

I took a look at the Haltech software for the R3 and I’m not sure its really gonna do boost control as suggested by ProperTuning.

Now I’m not as versed in Haltech as with others but it seems like “intake air bleed” is only a 2D table and a PWM output. Have others used a bleed valve more fancy then that?

R3 is also a 4 channel PDM, kind of enough to run an engine but certainly not an entire car.

You’ll also want a bleed valve, not a DBW throttle body. I’ve been part of an emtron car (since they really popularized this whole thing) and they used a modified DBW throttle that the neutral position was closed. a DBW throttle usually springs back to 12% open roughly. There is an audi valve from I think it was V6 supercharged engines that’s more ideal for this imo

Funny you bring up Emtron, lol. We were the west coast USA tech for a while, so we are very familiar with the way all the TMF and air calcs work.

If a DBW throttle is used, it itself has to have full H bridge throttle control, you treat the valve as another throttle. Then you map the throttle area to the boost DC command rather than a TQ or pedal command. So now you have a second PID. One is the throttle PID, the second is the boost control. Again, a non linear flow will occur, so a direct linear DC command like normal boost control will not result in stable control.

On the fail safe side, this is why we use the throttle that fails to 100% open. Even at 12% you would be capable of almost full boost, again non linear flow.

Where can one find these by pass valves. Or dbw that rest at an open position.

Audi bypass 057128063G

Mercedes bypass 0280750467

Mopar bypass 68170670AF

I’ve used the audi bypass, 48mm blade and very sturdy, virtually zero leaks when fully closed