Im pretty new to this so I apologize in advance for this basic question. I have a jeep i6 engine with 36-1 crank trigger and single tooth cam trigger. I get a clear crank and cam signal on the scope but my ecu will stay inactive and I have no sync on ignition status. Any information of where I should be looking for my mistake in ecu setup are greatly appreciated

post your map, log of a start attempt when the issue occurs and that scope log.

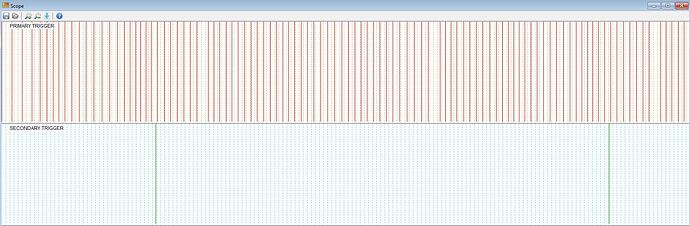

Probably just a trigger setting issue as that looks like a clean scope log for a 36-1 wheel and a 1 tooth cam

jeep i6.emulog (93.1 KB)

Heres what I believe to be a log of when the problem is occurring. It wont let me upload my map because it says its the wrong file type, but I can only save the map as a .emu

20250728_1842.csv (248.1 KB)

I saved the scope log as a csv file since it also wont let me upload a .emuscp

hmm I’d use a google drive link or similar then.

That is a new forum issue, as I just tried to upload a emu classic file and a scope and neither will work…

the scope log I am now seeing didnt turn out very good. One thing I noticed in the first log I posted was that the cam sync trigger tooth is erratic. If I understand correctly it should just be up and down since its a single tooth?

You’ll need to change access to “anyone with the link”

Scope log you first posted looks good, I want to measure the tooth count between secondary events.

Ecumaster’s scope doesn’t show the tooth shape, it’s not an oscilloscope type view like Link or Haltech. Instead they give us a line at the time the ECU (based on the settings) ‘sees’ a tooth. So each line is a “tooth event”

I think I have fixed the access problem now.

alrighty, now that we got all the info I’ve taken a look.

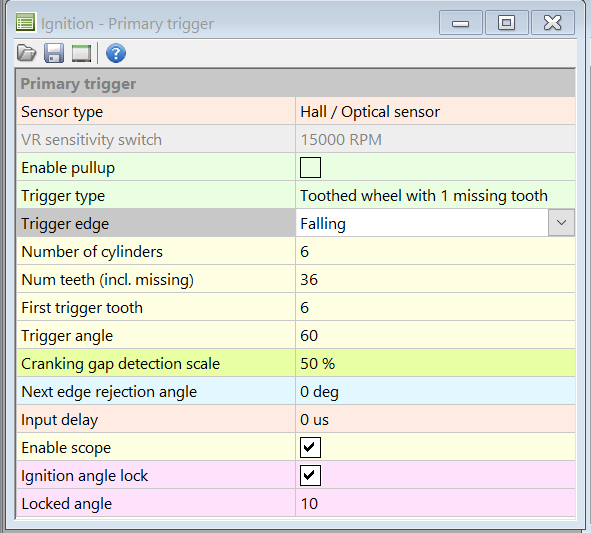

Trigger settings; I always prefer falling edge over rising. I find it more stable, but that said the trigger scope does look clean and consistent. I’d try falling edge for both cam and crank and see if that changes anything. (this will require re-timing with a timing light)

I also don’t know these jeep engines but seems odd to me that the crank position sensor doesn’t need a pull up but the cam does. Just want to clarify that is the case as that is odd to me. Looking up diagrams they both appear to be hall effect type.

What I do see is the cam sync tooth is moving around through cranking, this is probably why the ecu is reporting rpm but not synchronizing. The cam signal present parameter is cycling rapidly, so perhaps there something to that pull up or edge selection that we can’t see with the more basic EMU scope log.

As a test I would disable cam sync and put the ignition output in waste spark. see the screenshot below

The cam sensor is a factory jeep sensor, but the crank is not factory. I machined the harmonic balancer to have the 36-1 pattern (my whole reason for going with a standalone ecu is that I kept melting the factory crank sensor due to its close location to my turbo). The crank trigger sensor is from the diy auto tune website. so pull up was not needed for the crank trigger but was needed to the cam trigger to work. They are both hall effect type sensors though so might this point to a specific issue?

so far I have not been able to set any timing as the ecu wont fire the coils when its not active. I did not realize I could run this with out cam sync so I’ll try that and report back.

I have changed those settings but still get no spark output or emu synchronization. There was a moment it was trying to sync after I let off the key but it did not do that as consistently this time. This did make me double check my wiring/ pinout again to verify I have the coil outputs at the right pins on the ecu and there is less than 0.2 ohms on all the coil signal wires.

You can use output tests to check if the coils are working. But if the ecu isn’t synchronizing then you won’t get any spark outputs until it does. See the log parameter for “executed sparks count”

Time to think a little more outside the box, let’s try changing the triggers settings to within Ecumasters intended parameters. see the photo below but change the first trigger tooth to 6 and angle to 60. help file recommends and ideal number of 50-60 degrees in there.