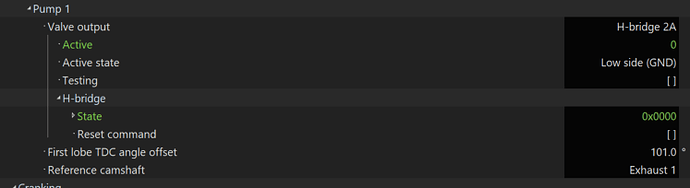

We are attempting to use H Bridge 2A to control the GDI pump, it is wired to the GDI driver as if we were using an injector out and its setup according. Is this setup correct? I never see an active state unless I manually trigger. I also get no pressure being built, I know the setup is correct. We are running 8 port injectors now as well, so I needed all 16 injector outs.

Also, is there any way to make cranking choose a split weight table or rail?

The setup seems correct.

Please send me the project to marek.kuklis@ecumaster.com

We will try to simulate it and reproduce the issue.

Not now. Cranking is always from rail 1.

Do you want to start the engine with port injection?

1 Like

I will verify my setup again tomorrow before I send anything. I think I may have had a possible fuel supply issue. Pulled the supply line for the DI pump and a ton of air came out. If I manually trigger the H bridge, I can hear the solenoid actuate. I will verify and let you know.

As far as port injection, we like the ability to fall back 100% to either port or DI.

@mkuklis_ECUMASTER

Engine is running now, no problems. Thank you for the offered support. I’ll send the config over once we get off the dyno. Gen 3 5.0 Coyote, 8 port, 8 di injector factory. This one also has a 4L80E, so I will be testing and reporting.

@mkuklis_ECUMASTER

I’m bringing this back up because I need to see if there is any way to add the ability to crank off of Fuel Rail 2? These dual injected coyote engines seem to bleed off over night and have a low pressure startup in the factory calibration. We are having issues at this point in the mornings.

We are currently analyzing how the Camaro engine starts in OEM configuration so we can duplicate that strategy. It has no port injection, a big engine that turns slowly, yet it can start very fast.

We will also add the option to select the rail for cranking.

2 Likes

I hope you mean GM’s LT1 engine. I’m actively looking for an ECU solution for a customer’s car.

Yes, LT1.

The car is driving, and the engine is mostly tuned.

We are currently working on the details, such as the aforementioned start strategy.

We are also working on the CAN communication with the 8L gearbox, but that needs a bit more time.

That’s great news! The car is already using ECUMaster components (PMU, bridges, battery isolator, keypads, etc.) Using a PRO-8 and an ECUMaster GDI would make for a complete solution.

In this case, the car is using a ZF 8HP70 and CANTCU transmission interface. I have engineering support lined up for that already, and the open nature of the PRO ECU will really help.

1 Like

We will have the same combo running soon. Along with L8T, L8P, LT4 and 8HP95.

Getting the LT1 to run will be a pretty easy thing.

Very cool. Are you using GM sensors? The car will be using a Holley front kit, so the coolant temp sensor might be the only aftermarket sensor on the car. What about the DBW and throttle pedal. GM as well?

Yes all GM sensors, SENT as well. The nice part is, it really doesn’t matter if you want to change that stuff.

Obviously we do not use the MAF. No need.

Right, understand. No MAF is good. I’ve done enough MAF combined with virtual speed density tuning in HP Tuners to last a lifetime.

Glad to hear about SENT – that was my next question.

1 Like