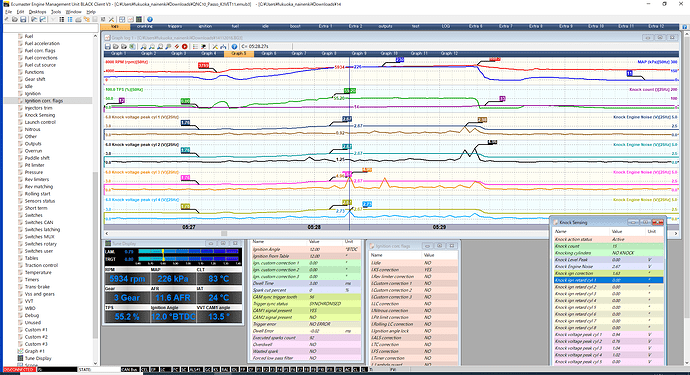

Seems like a bug in Knock action status log channel control.

I will check.

My understanding of knock control is as follows, but is it correct?

・When the signal level from the knock sensor exceeds engine noise, ignition retard is generated by the value/V set by Ignition retard rate.

However, since previous versions of the firmware, a retard higher than the actual expected value has occurred, so I suspected that the retard value was determined only by the signal level without taking engine noise into account.

Furthermore, even when the Knock ign corection value is increased, the Ignition From Table and IgnitionAngle values remain the same.

Is this phenomenon seen in the log also a problem only with the display of the log channel, and is it actually controlled correctly?

The Connection was ok yes, and the gearbox also is free and already with a tuned software.

Can you check at your a3 it is a R32 with dsg or?

If at shift it is sending NM not 0?

i drive on dq500, not see the problem when shifting

Is it simply a specification that there is a time lag between the knock level on the log window and the knock level on the graph?

On the graph the threshold is not crossed but in the log window the peak is 2.49V.

I apologize for posting multiple times in a row, but the EDL-1’s timestamp doesn’t work properly in my environment.

Specifically, the time part is correct but the date part is off.

I think the above log would be created in the main 2025/04 directory under the name 06112018.BG3, but it is created in the 2000/01 directory as 14112018.BG3.

Set the real time clock at thr longer. In tools section

Thank you for your reply.

Are you referring to Set Datalogger time in the Tools section?

I’ve tried that many times already but it didn’t work.

The time is displayed correctly, but the date doesn’t change.

The internal battery of the EDL-1 is also fine.

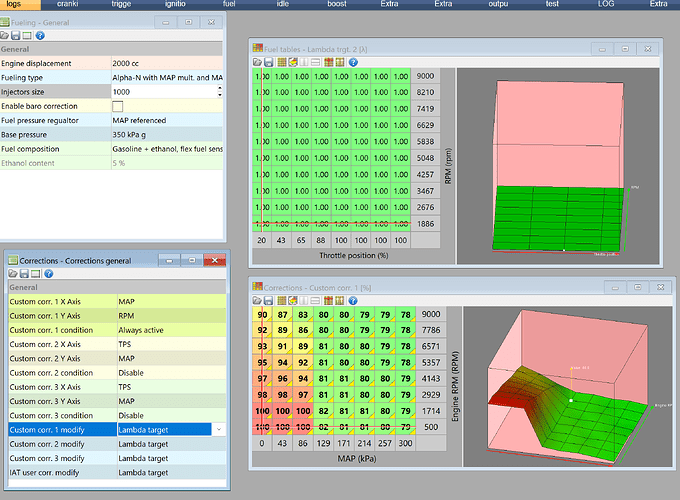

Hi, SI’m using the Alpha N with map multiplication statergy (turbo ITB). The lambda target table is TPS based now where as is used to be MAP based in V2. Is this the correct way to be able to target 0.8 lambda when I’m on boost? Using thr correction tables

Wow, y’all have been busy. Looking forward to trying out all of the new improvements.

As always, great work, it’s much appreciated.

On the V3 software? From what car is that gearbox? What production year?

Yes, on V3. Audi A3 2005, gearbox QYQ from audi Q3 2016.

So this is not an MQB DQ500. You have the continental mechatronics, right?

Not MQB mechatronics-right, Audi Q3 till 2018 have PQ mechatronics, without component protection.

Andrei, do you have a full backup of the Continental TCU mechatronic?

Can we get Can analog in for nitrous pressure sensor?

For example im using meth injection with pressure sensor, nitrous strategy working perfect for it.

It appears when typing some values in the functions window the UI display differs from the actual set value. For example I actually typed 0.75 in the ‘Constant:’ box, it automatically changed to 0.8 bar as you lose focus from the box. Although when you press OK on the Operator function window, it actually shows the value you typed in the main user function window…

Also, maybe another UI bug, the 0 (zero) key on the keyboard number pad does not work in the ‘Value’ box (circled red), yet the 0 (zero) key on the top row of numbers does.

Hi,

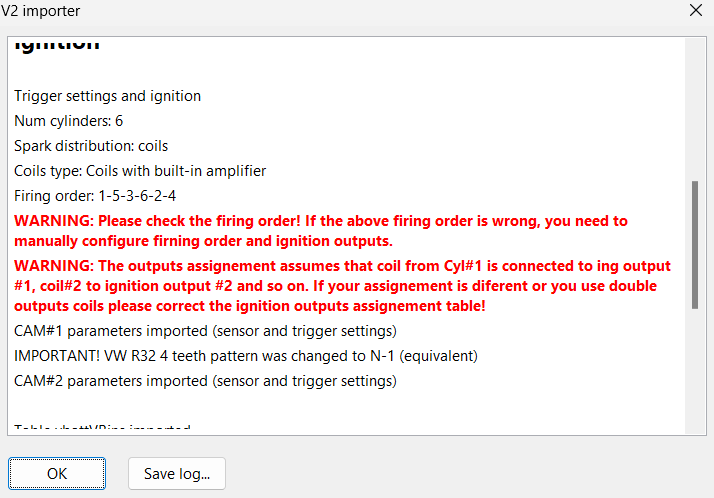

I have noticed that the trigger wizard sets the secondary trigger pattern to N+1 for the R32 BFH/BUB however if i import my V2 file it sets it to N-1

Since updating to 3.047 I’m now getting issues with my idle, occasionally stalling. I noticed in the release notes it mentions recalibrating the throttle. I’ve tried this but still having issues. Anyone else experience this?

Also when opening a log file from EDL-1 occasionally the log fails to open. I’m having to close the software and reopen for the graph log to appear.

I tried to use n-1 with bub engine without success

is it possible to have a correct cam or trigger offset? In my Configurations n+1 the first tdc is 13 tooth is correct?

Aux 3 is possibile to delete the fn1 for intake valve? I use aux3 and this wire for overboost solenoid

And is a problem not use a mass flow meter? But i have a fuel problem whit 2 weeks (after 1,67ms and 0,97 effective….past 1,8ms but 0,46 effective)

The original oil level and temperature sender don’t work, is possibile this phenomen work whit a oil switch and open or don’t open the second oil Line?in 2 years Is 3 think the car smoke oil and for 2 think this problem is solved in magician mode an 2/3 update but I don’t understand the origin of the problem