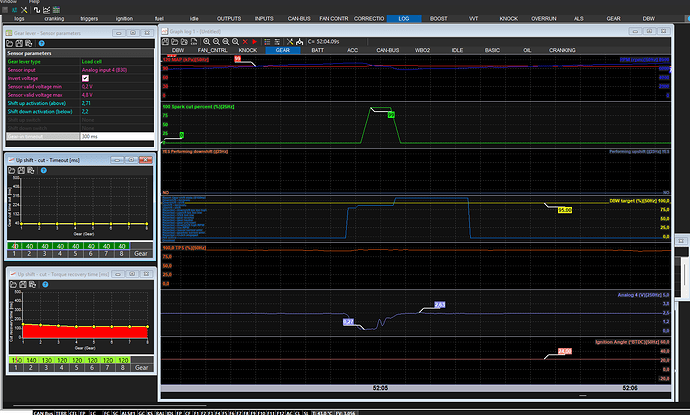

Im trying to set gear cut strategy on seq trans and load cell on analog 4 and cant get spark cut right on treshold, it still happening on recovery time…is it my fault or it cant be set that way?

Please send your configuration and the log. I will analyze and advice.

2025_09_20_P106_new_gearcut-the-best.emub3 (67.0 KB)

20250920_1941-tensometer2.emublog3 (7.8 MB)

There was a lot of settings i tryed…but im missing the main logic…Why i cant cut spark right on reshold? Why there is minimum 40ms timeout?

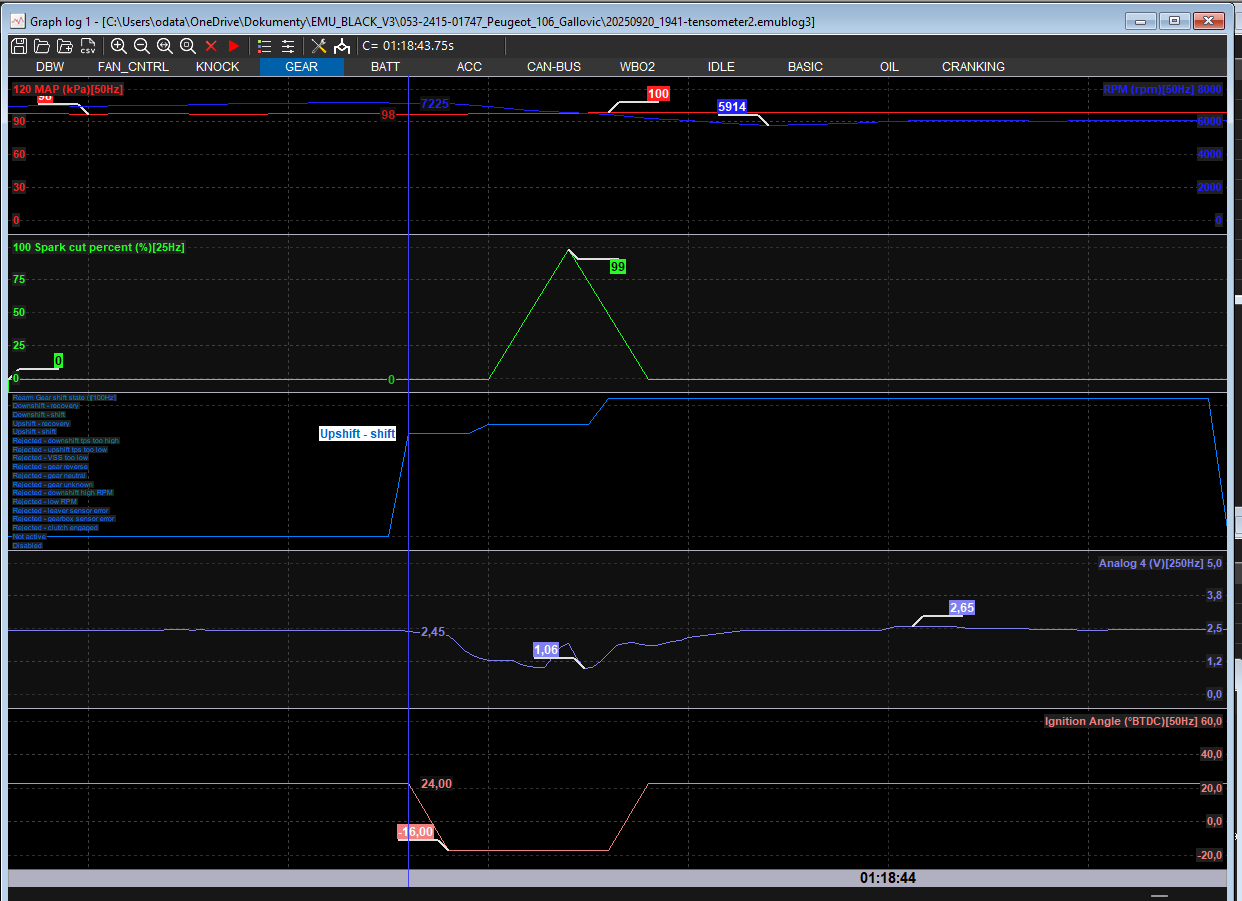

This is the timeout not delay. The table specifying the maximum duration of the cut phase during the gears upshift strategy. So for sure 40ms is too short.

The spark is performed as soon as loadcell condition is met.

Spark cut can not be performed as soon as load cell condition is met…as the log shows…under the upshift phase ignition retard only happening and under recovery time happening the spark cut? Do you agree?

Let me the time to analyze data and found the issue. In most situation the problem is with the improper voltages for gear sensor.

I will analyze it today evening.

The problem is that you use the gear shift strategy in kind unusual way.

In your case your gear is all the time 0 and when you try to upshift the cut is not performed as the strategy thinks you try go from neutral to 1. Also you the gear unknown flag is set all the time, as you select gear detecion strategy to sensor, but the sesnor is undefined.

In 3.047 in the case the gear is unknown the strategy assumes that selected gear is 1.

But it had some unwanted side effects during shifiting and it was removed.

For the next build I add an rule that if the gearbox sensor status is other than ok, and geabox sensor is selected as a gear source, the gear target for upshift will be fixed to 2. It will solve your problem.

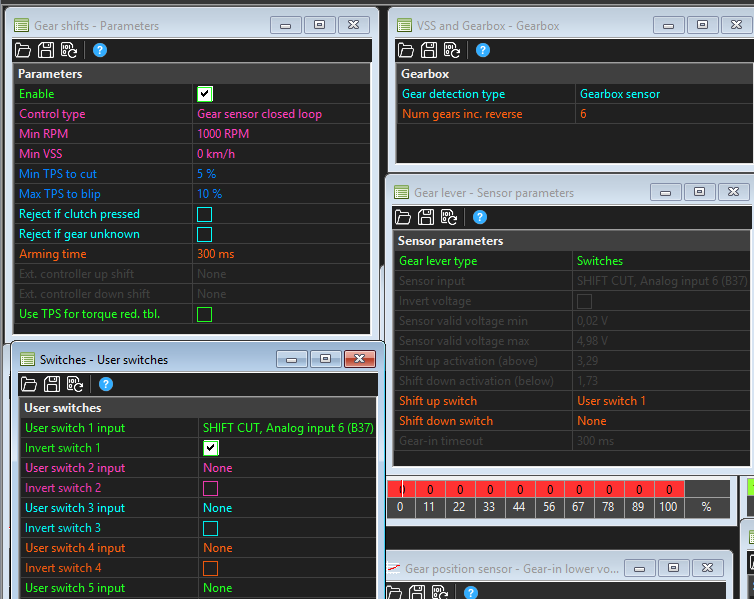

Allright…The setup is like this because car has OEM dash and only a small led display to show selected gear…so i want to run gear cut on very simple way…Can you give me any advice how to work with that for now? Car will race on Slovak national rally championship next weekend…Can i define gear sensor and calibrate to 0v = second gear and will it solve the issue or it will doesnt work without gear sensor connected?

Also is it possible to redo inverted voltage strategy for load cell? its a little wired way to set tresholds now

Thank You Jakub ![]()

Use analog 4 as a gear sensor and configure voltages to show always gear 1.

It should solve your issue

I have to use analog 4 as gear sensor? Because im allready out of analog inputs and running analog 4 on load cell for fast logging….can i deffine can analog input as gear sensor?

If you dont have gear sesnor then use analog 4 that you use for load cell. It will be verybeasy to configure gears then.

If you have gear sesnor I strongly recommend use close loop as it is much safer for gearbox and then use analog 4 as you need high logging frequency for setup.

A

And use timeout longer than 40ms. For open loop use much longer time

Its working with new update very well…thank you!

Another question is if im using switch for gear cut…what is the best way set it up? Using switch input is not a best way because of debounce time and if i connected to the analog input i cant set in gear cut strategy that as switch….if i set load cell i running in trouble with min/max vailid voltage

You can easily “simulate” a load cell with the switches. You need to use two resistors (eg. 10K) to create voltage divider to get 2.5V and then another 2 10K via switches to +5V and to GND to get voltage above 2.5V for upshift and below for downshift

I dont like use resistors in wiring harness if its not the only solution…so i decided to try user switch and its working as i want…i dont know if there is any disadvantage but it seems okay to me even in closed loop mode

It gives around 10ms delay for debouncing.